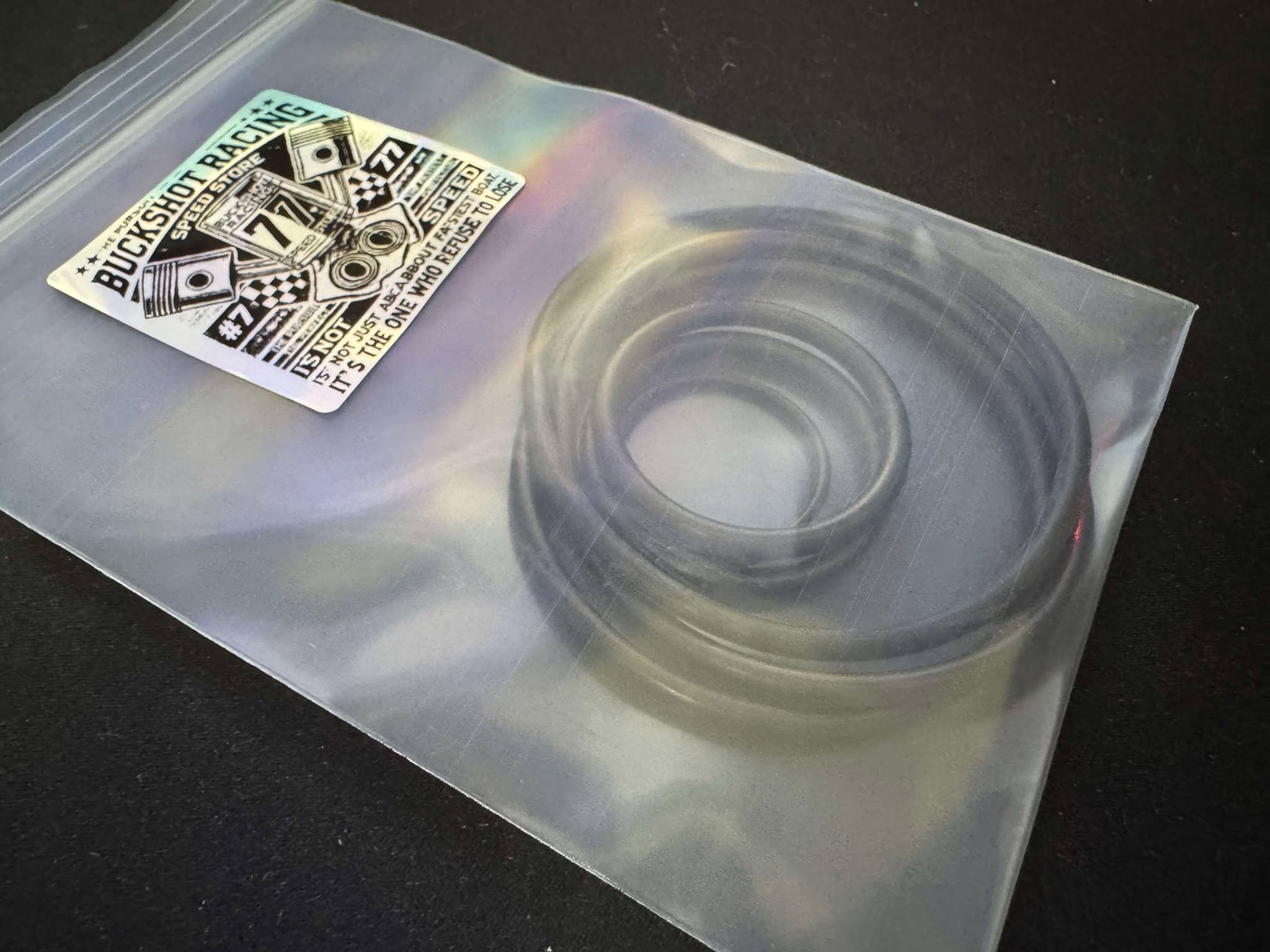

The Mercury Outboard Power Trim Cylinder Repair Kit 79879A1, also sold as the Buckshot Racing #77 O-Ring Kit, is a high-quality OEM-equivalent solution designed for rebuilding single-ram power tilt and trim cylinders on Mercury V6 2-stroke outboard engines.

This kit restores hydraulic performance, eliminates leaks, and helps maintain smooth trim and tilt operation. It is compatible with earlier 2.0 and 2.4-liter stock fishing outboards and offshore performance applications, including ROS (Race Offshore Series) models.

This rebuild kit is ideal for common Mercury 2-stroke V6 engines: Mercury XR2, XR4, Mercury 2.0L, 2.4L, 2.5L V6 engines, Black Max, Pro Max, Bridgeport, Offshore 2.5 ROS V6 2-stroke outboards with long trim rams.

Full Mercury Power Trim Cylinder Rebuild Guide

Before beginning, arrange a clean, lint-free workspace, as contamination can cause premature seal failure in the trim system. Disconnect the hydraulic hoses and remove the trim cylinder from the outboard, following procedures outlined in the Mercury Marine Service Manual, downloadable for free in the "Tech Hub" section of our website

Once removed, direct the up and down hydraulic ports into a suitable container and pump the trim rod in and out several times to fully drain the system.

Use a pin spanner wrench to unscrew the rod guide and remove the trim rod assembly. Remove the floating piston by gently tapping the cylinder against a wooden block, if necessary.

Discard the O-ring from the floating piston. Next, unbolt the shock piston from the end of the trim rod to access the large washer and internal hydraulic components.

Remove and discard the used O-rings, compression springs, spring guides, spring seats, and check balls from the shock piston.

Disassemble the rod guide by removing it from the trim rod. Remove and discard the retaining ring, plain washer, scraper, and the three O-rings.

All discarded seals should be replaced with new components from the 79879A1 repair kit.

Clean all reusable parts with a non-toxic solvent and thoroughly dry them using compressed air. Inspect parts for wear, and replace any components that are damaged or out of spec.

Prior to reassembly, lubricate all internal components with SAE 10W-30 or 10W-40 motor oil. Install three new O-rings onto the rod guide, followed by the scraper, washer, and retaining ring.

Slide the rod guide onto the trim rod. Rebuild the shock piston by installing the new check balls, spring seats, compression springs, and spring guides, followed by two new O-rings.

Place the shock piston and washer on the trim rod, then apply Loctite 271 thread locker to the piston rod bolt. Torque the bolt to 58–72 ft-lbs (8.02–9.95 kg·m) as specified by Mercury.

Install the new O-ring onto the floating piston and insert it blunt-end first into the cylinder. Carefully reinstall the trim rod assembly, then thread the rod guide into the cylinder body and tighten it securely. Reconnect the hydraulic hoses and ensure all fittings are properly torqued.

Cycle the trim system multiple times to ensure full range of motion and leak-free operation. This rebuild process is vital for maintaining consistent performance, especially in high-demand marine environments, offshore racing, or heavy-duty recreational use.

The Mercury V6 2-stroke power trim cylinder is critical for efficient engine trim and tilt functionality. Using the 79879A1 trim repair kit or the Buckshot Racing #77 kit ensures a precision fit for your Mercury Marine engine, preventing hydraulic failures and restoring smooth, consistent operation.

This repair procedure applies to many Mercury and Mariner models manufactured from the late 1970s through the early 2000s.

Contact Mike Hill at +1-714-697-1716 or email mike@buckshotracing77.com for technical support.

top of page

SKU: SROR-77

$29.00Price

bottom of page