Mercury V6 2-Stroke Firing Order

.JPG/v1/fill/w_320,h_320/file.jpg) Mike Hill

Mike Hill- Apr 9

- 3 min read

Updated: Apr 12

The Mercury 2.0, 2.4, and 2.5 Liter V6 outboard engines uses a wasted spark ignition system, a design choice that simplifies electrical complexity for the EFI system while maintaining reliable performance.

In this system, each of the six cylinders fires once per crankshaft revolution, as is standard for a 2-stroke engine. However, instead of having a dedicated trigger signal for each individual cylinder, the engine uses just three trigger coils, each of which controls a pair of cylinders.

These pairs share a common timing signal, which causes both cylinders in the pair to receive a spark at the same time — this is where the term "wasted spark" comes into play.

Only one cylinder in each pair is on its compression stroke at the moment the spark occurs. The other is on its exhaust stroke, so its spark plug fires into a cylinder that contains only spent exhaust gases.

This second spark does not ignite anything and is therefore considered "wasted." Despite this, the system is highly effective because it reduces the number of components required, particularly within the ignition electronics. It allows a single trigger event to serve two ignition coils, simplifying synchronization and improving reliability.

For example, trigger coil A might control ignition coils for cylinders 1 and 4. When the engine rotates to the point where cylinder 1 is on its compression stroke and ready to fire, cylinder 4 is simultaneously on its exhaust stroke. Both receive a spark, but only cylinder 1 combusts the air-fuel mixture.

On the next revolution, the roles reverse — cylinder 4 is now on compression and fires for real, while cylinder 1 receives a wasted spark on its exhaust stroke. This alternating pattern continues across all three pairs: 1 & 4, 2 & 5, and 3 & 6. Firing events are spaced every 60° of crankshaft rotation, making it an even-firing engine.

This system is especially well-suited for 2-stroke engines like the Mercury V6, where every cylinder fires once per revolution and there are no intake / exhaust valves to complicate ignition timing. The simplicity of the wasted spark method allows for high performance with fewer moving parts and less electronic control hardware, without compromising engine efficiency or reliability.

✅ 1. Firing Order: 1-2-3-4-5-6

This is evenly spaced every 60 degrees of crankshaft rotation — exactly what you expect from a 2-stroke V6 where each cylinder fires once per revolution. No gaps or irregular timing = even firing.

✅ 2. 2-Stroke = 1 Fire per Revolution per Cylinder

Every cylinder completes a power cycle every 360° (vs. 720° in a 4-stroke). That’s why the crankshaft turns once, and all 6 cylinders fire sequentially.

✅ 3. Wasted Spark System is Used

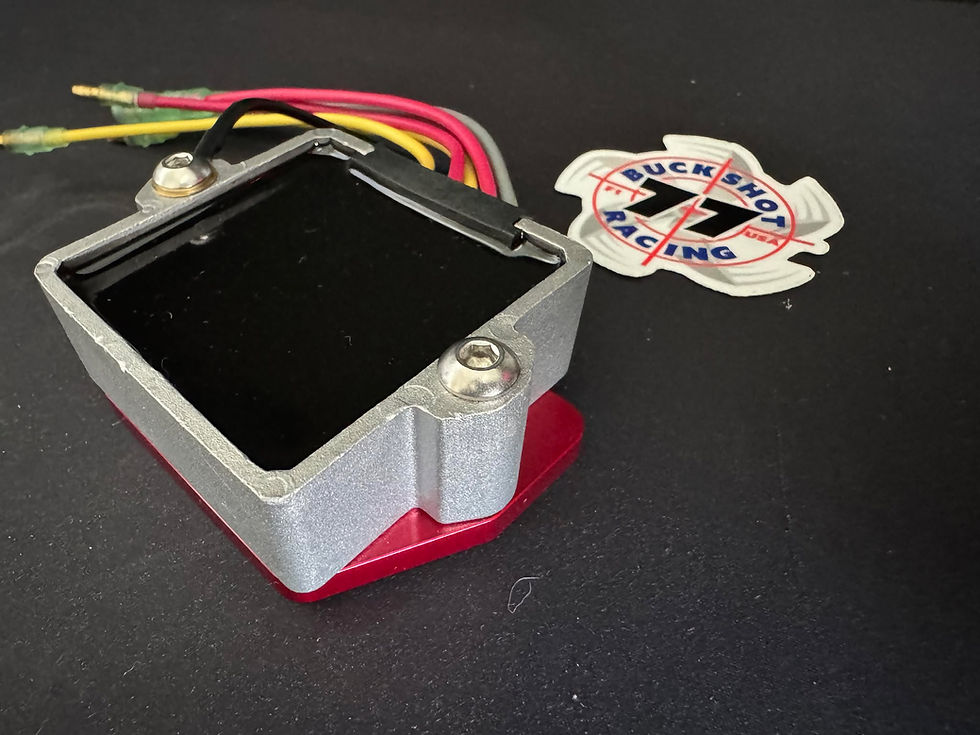

3 trigger coils and 2 switch boxes, each handling pairs of coils. This is textbook wasted spark configuration. While both plugs in a pair spark at the same time, only one is on compression. The other is on exhaust → wasted spark.

✅ 4. Pairs Are Electrically Linked, Not Mechanically Paired

Electrically, coils 1+4, 2+5, 3+6 are paired — they spark together. Only the one on compression stroke gets a useful combustion.

✅ 5. Every 60° of Crank Rotation = One Fire

Because the crankshaft rotates 360° per revolution and you’ve got 6 firings, that’s one spark every 60°. This is confirmed by the design and matches the behavior of even-firing 2-stroke V6s.

WHY THIS WORKS (AND WHY IT'S USED)

✅ Pros:

Fewer trigger signals needed: Only 3 trigger coils for 6 cylinders.

Simple electronics: Makes the system cheaper and easier to troubleshoot.

Works fine in 2-strokes: There’s no intake/exhaust valve timing like in a 4-stroke, so overlapping ignition isn’t a problem.

❌ Cons:

Slightly more wear on spark plugs (but minimal)

Tiny amount of unnecessary energy is used (but not noticeable)

Kommentare